How airlines keep aircraft from tipping over

Last weekend, after landing safely at Lewiston Airport, Idaho, a United Airlines aircraft ended tipping backwards as it was being unloaded on the ramp. Photos show the Boeing 737-900 sat back on its tail with its nose up in the air, with the front cargo compartment open as baggage unloading was taking place.

In a statement to The Points Guy, United said that "United flight 2509 flying from Los Angeles, California to Lewiston, Idaho landed without incident. Due to a shift in weight and balance during the offloading process, the tail of the aircraft tipped backward. No injuries were reported among our customers, crew or ground personnel. The return flight was on a different aircraft as originally planned."

An aircraft is more than just a lump of metal which pilots take into the sky. There are more variables at hand than you might imagine, especially when it comes to the loading of the aircraft.

Want more aviation news? Sign up for TPG's free newsletter!

Not just raw power

Each time an aircraft gracefully soars away from a runway, there's far more going on than meets the eye. As important as the engines are, they are only a small part of what it takes to get airborne. In order to fly, an aircraft needs lift and this lift is generated by air passing over the wings.

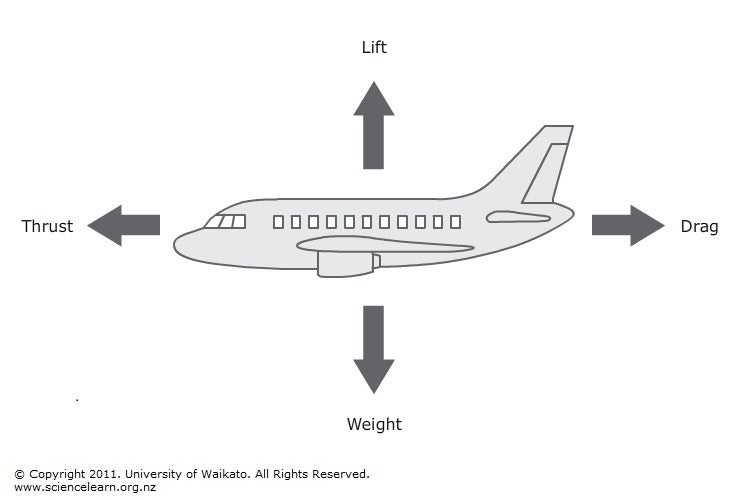

At any given time, there are four forces acting on an aircraft. In the horizontal plane, thrust drives the aircraft backwards and drag slows the aircraft down. In the vertical plane, weight forces the aircraft towards the earth and lift directs the aircraft into the air.

When all these forces are equal, the aircraft is stationary. However, if one force becomes greater than the other in the same plane, the aircraft will start to move.

The obvious example of this is when we power up the engines to start the take-off run. The forward thrust generated by the engines exceeds the drag on the aircraft caused by the air and friction with the runway, so the aircraft accelerates. With the aircraft accelerating, the wings cut through the air or, seen from the flip side, the air accelerates over the wings. As this airflow continues to speed up, something magical begins to happen.

Due to the shape of the wing and the angle at which it hits the air, it starts to generate lift. The faster the air flows over the wing, the more lift is generated. More and more lift is generated until a precise moment where the lift generated almost exceeds the weight of the aircraft.

At this moment, we pull back gently on the control column, causing the control surfaces on the horizontal stabilizers just under the tail to deflect up into the airflow. This pushes the tail down towards the runway and, as a result, the nose up into the air. This is known as 'rotating'. As the aircraft rotates, the angle at which the wings hit the air increases, creating even more lift and all of a sudden the lift generated is greater than the weight of the aircraft.

It is at this moment that the aircraft begins to lift away from the ground, as can be seen in the video below.

However, how do we know that when we pull back on the control column that the tail will sink lower to the ground and the aircraft will rotate? This critical moment of flight can be traced back several hours to when the aircraft was still at the gate.

Mass & Balance

How the aircraft is loaded plays a critical role in the safe departure, cruise and arrival of a flight. A typical long-haul flight may have 250 passengers, a similar number of suitcases plus freight which is carried in the cargo compartments along with the baggage. It is these factors that provide the variables in the loading of the aircraft.

All aircraft act like a see-saw at a kids playground. If the weight at each end is the same, the see-saw stays horizontal over the central pivot. However, if the weight at one end of the see-saw exceeds the weight at the other end, the heavier end will drop to the floor – like the 737 incident.

That said, it's not always as simple as this. If a heavier child sits halfway up their side of the see-saw, a lighter child at the end of their side will drop to the ground – it's all to do with the distance from the pivot.

On an aircraft, it's similar, but the pivot point, or center of gravity (CoG), isn't always in the middle. When certifying the aircraft, the manufacturer calculates where the CoG is for the empty aircraft. If the passengers and baggage were always uniformly distributed throughout the aircraft, keeping the aircraft balanced, or 'in trim' would be straightforward.

However, this isn't always the case. If first and business class is full but economy is relatively empty, the majority of the passenger weight is focused at the front of the aircraft, giving it a forward center of gravity. Conversely, if all the passengers are at the rear of the aircraft, the center of gravity will move towards the rear of the aircraft.

As a result, during the design stage of the aircraft, the manufacturer will not only determine where the empty CoG is, but will also determine a safe range for the loaded CoG.

It is the responsibility of the loading department to ensure that the CoG remains within this safe range.

Keeping it Balanced

This is fine if the passenger load falls naturally within the CoG range, but what happens if, like mentioned above, economy is full but business and first is empty? With all that weight at the rear, there's a good chance that the aircraft could tip back onto its tail.

Before you get too excited that the solution to this problem is to upgrade passengers to even out the load distribution, let me tell you that it is not. Instead, the loading department uses the other variable that we haven't discussed yet. The baggage and freight.

Most large airliners have two cargo compartments, one at the front and one at the rear. Knowing where all the passengers will be sat, the aft CoG can be moved backwards or forwards by loading more baggage into one hold or the other.

Aircraft are at their most aerodynamic with a slightly aft CoG. As a result, the loading department will try to balance the aircraft so that the CoG is slightly towards the rear of the neutral point.

Once all the passengers have checked in and the flight is closed, the loading department can then determine exactly where the baggage needs to go so that the flight is safely in trim. This is why airlines have to close check-in a certain time before the flight departs, to give the staff time to ensure that the aircraft is safely loaded.

Every so often, the loading has to be done in such a way that could leave the aircraft unstable if the passenger distribution changes. This is why, particularly on an empty flight, passengers must sit in their allocated seats.

In these situations, when arriving at the destination, ground staff may require passengers to remain in their seats until they have offloaded some of the baggage and cargo. Once this has been done, and the aircraft is safely balanced, the passengers may then disembark.

ULDs, containers and pallets

On smaller aircraft types, baggage is loaded by hand directly into the cargo holds. They are stacked up and secured by netting to stop them from moving around. However, on a larger aircraft such as the 787 Dreamliner, there could be hundreds of bags plus an enormous variety of freight.

To make the loading and unloading process quicker and easier, ground staff use unit load devices (ULDs) such as containers and pallets.

Baggage containers

Containers are primarily used to load passenger baggage and are a standard shape and size to fit a range of aircraft. For example, an LD3 container will fit in A330, A340, A350, A380, B767, B777 and B787 aircraft types. This gives airlines great flexibility when operating a fleet of different aircraft.

As bags arrive from the check-in desks to the loading zone under the terminal building, ground staff begin to load them into the containers. Even with a container, the bags are not thrown in randomly. They are packed like a giant 3D jigsaw puzzle to ensure that the weight is evenly distributed and so that the bags don't shift position in flight.

As each bag is loaded, the tag is scanned so that a record is kept of which bag is in which container. Should a passenger fail to make it to the gate on time and they are offloaded from the flight, their baggage must also be removed.

Instead of searching through every container for the bags, the ground staff can look at the log and see in which container the bags have been loaded. It's then a question of accessing the correct container and removing the bags.

This process saves time, allowing the loading process to begin even before the aircraft has arrived and then reducing lost time in the event of baggage offload.

Freight pallets

Freight comes in all shapes and sizes so it's not always possible to load it into baggage containers. As a result, freight tends to be loaded on pallets, which can then be put into the aircraft in the same fashion as the containers.

The versatility of the freight pallets enables them to carry all sorts of goods. Avocados, fresh-cut flowers, salmon, live eels, car engines, lawnmowers. The list is almost endless. Aircraft sometimes even carry human remains when a deceased person needs to be reunited with family in another country.

Take-Off Performance

With the holds carefully loaded to ensure that the aircraft is safely balanced for departure, the pilots can then calculate their take-off performance.

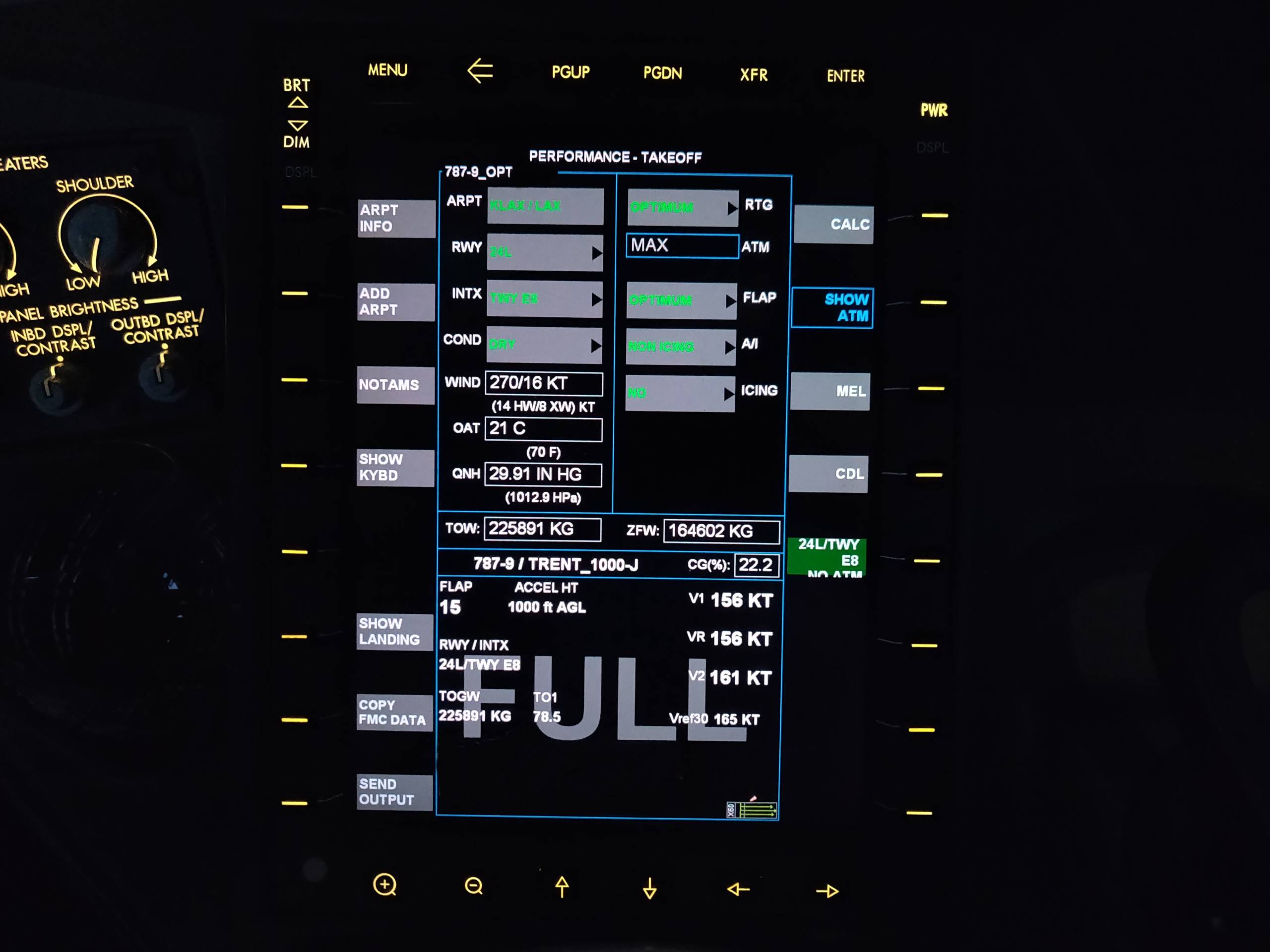

Aircraft don't just get airborne by luck. We know exactly how much runway is needed, how much engine power to use and what speed to lift off at. To calculate this, we use the Onboard Performance Tool (OPT).

The OPT enables us to enter the airfield weather information and, using the take-off weight and trim setting given to us by the loading department, calculate the takeoff performance. This is one of the most critical stages of the flight. An error here could have serious consequences on the takeoff run.

It is by correctly calculating these figures that we know for certain that when the critical moment comes when we pull back on the control column approaching 200 mph, our 220-ton metal see-saw will indeed sink back on its tail, its nose will rise into the air and the aircraft will climb gracefully into the sky.

Bottom Line

The way in which an aircraft is loaded is critical to the safety of the flight. Too heavy at the rear and it could tip onto its tail. Too heavy at the front and the pilots will struggle to get the aircraft airborne. As a result, cargo and baggage are loaded in a way in which they will balance out how passengers are sat in the cabin.

The load sheet provides the pilots with information as to how the aircraft has been loaded. From this, we are able to set the trim of the horizontal stabilizer to ensure that all takeoffs handle in the same way.

TPG featured card

at Capital One's secure site

Terms & restrictions apply. See rates & fees.

| 5X miles | Earn 5X miles on hotels, vacation rentals and rental cars booked through Capital One Travel |

| 2X miles | Earn unlimited 2X miles on every purchase, every day |

Pros

- Stellar welcome offer of 75,000 miles after spending $4,000 on purchases in the first three months from account opening. Plus, a $250 Capital One Travel credit to use in your first cardholder year upon account opening.

- You'll earn 2 miles per dollar on every purchase, which means you won't have to worry about memorizing bonus categories

- Rewards are versatile and can be redeemed for a statement credit or transferred to Capital One’s transfer partners

Cons

- Highest bonus-earning categories only on travel booked via Capital One Travel

- LIMITED-TIME OFFER: Enjoy $250 to use on Capital One Travel in your first cardholder year, plus earn 75,000 bonus miles once you spend $4,000 on purchases within the first 3 months from account opening - that’s equal to $1,000 in travel

- Earn unlimited 2X miles on every purchase, every day

- Earn 5X miles on hotels, vacation rentals and rental cars booked through Capital One Travel

- Miles won't expire for the life of the account and there's no limit to how many you can earn

- Receive up to a $120 credit for Global Entry or TSA PreCheck®

- Use your miles to get reimbursed for any travel purchase—or redeem by booking a trip through Capital One Travel

- Enjoy a $50 experience credit and other premium benefits with every hotel and vacation rental booked from the Lifestyle Collection

- Transfer your miles to your choice of 15+ travel loyalty programs

- Top rated mobile app