Can hot weather cause aircraft brakes to overheat?

A Spirit Airlines Airbus A320 touched down in Atlanta on July 11 after a short flight from Tampa. As the plane began taxiing to the gate, the crew was alerted to billows of smoke emanating from the plane's wheels.

The crew brought the aircraft to a stop to assess the situation; then, they requested emergency services be sent out to the aircraft to help deal with the problem.

In the cabin, understandably concerned passengers were asked to remain seated by the cabin crew and wait for more information from the pilots. Within a couple of minutes, the airport fire services arrived at the scene, where they immediately put out a small fire that had ignited around the aircraft's wheels. A tug was then used to tow the aircraft to the gate where the passengers disembarked safely.

Heat from brakes has caused minor emergencies for a number of aircraft over the last few months. Is it just a coincidence that these have also been some of the hottest months on record? Or can hot weather really cause an aircraft's brakes to overheat?

[table-of-contents /]

How do aircraft brakes work?

Before we dive into the details of how and if the weather affects the brakes, we need to know how the brakes on an aircraft work.

To stop a wheel from turning, be it on a bicycle or an aircraft, you need to apply a frictional force on the wheel. On a bike, this is done by using a cable to push the brake pads onto the rim of the wheel. On a car, the system is similar, pressing brake pads against the rotating disc rotor inside the wheel.

On an aircraft, the principle is much the same but on a larger scale, and it differs slightly among aircraft types.

The Boeing 787 Dreamliner has one brake unit on each of the eight wheels on the main gear assembly. These are controlled by the pilots pressing the tops of the rudder pedals under their feet, demanding the rate of braking which they require. This sends an electronic signal to the left and right brake system control units.

The brake system control units then send signals to the four electronic brake actuator controllers which control the rate of braking on the wheels. Each wheel has four electric brake actuators — a kind of piston that presses against the carbon brake discs.

The brake discs themselves are made up of two parts.

Firstly, there are the rotors. These are connected to the wheel by drive tabs (in the video below they are the black rectangles on the rotor discs). Since these drive tabs are in contact with the inside of the wheel, they spin at the same speed. Depending on the brake manufacturer, there are either four or five of these rotors on each brake assembly.

The second part of the discs is the stators. These sit around each rotor, are fixed in place and don't move. As the wheel turns, the rotors spin around inside the stators.

When the brakes are used, the four electric brake actuators apply pressure to the first stator. This in turn squeezes the stationary stators up against the spinning rotors, and it's this friction that slows the wheel down.

Brake temperature indication

With friction comes heat, and each brake unit displays its temperature on the wheel synoptic page in the flight deck. Here, numerical values relating to brake temperature are shown next to each wheel. A value between zero and 4.9 is in the normal range. When a temperature becomes 5.0 or above, pilots will receive an advisory message.

Should the brakes become too hot, there's a chance that the heat transferred to the wheels could cause the tires to explode. To stop this from happening, fuse plugs in the tires melt when they reach a certain temperature. This allows the air to release safely and the tires to deflate slowly.

Related: Flying with world leaders: How pilots land big aircraft at small airfields

What happens on landing?

On touchdown, an aircraft like the 787 — which weighs about 192 tons — can be traveling at nearly 180 mph. That is a lot of energy that needs to dissipate as the aircraft decelerates on the landing roll, and most of it goes into the brakes.

As a result, before the plane gets anywhere near the ground, pilots perform a landing data calculation in the calm of the cruise. This has several functions.

First, and most importantly, pilots need to know that they are able to stop safely on the available runway length, considering the expected weight and weather conditions at the time of landing. If it turns out that the runway is too slippery to stop before the end, pilots must decide whether to wait for the runway conditions to improve or to divert to another airport.

When driving a car and approaching a junction, drivers don't go as fast as they can and then slam on maximum braking. Not only would this increase the chances of sailing through the red light, but it also causes unnecessary wear on the brake pads. Plus, it's particularly uncomfortable for passengers.

Instead, drivers either apply a braking force that brings the car to a safe, comfortable stop at the red light, or they start braking farther away from the junction to reduce the braking pressure required.

The same principles apply to an aircraft. However, since there is a defined length of runway available, the only way to change how quickly the plane stops is by varying the braking pressure. Yet, there is a trade-off to be made.

Use too little braking and pilots run the risk of going off the end of the runway (bad). Use too much braking and they run the risk of the brakes overheating and catching fire (also bad). As a result, it's crucial to find a happy medium that allows the plane to stop safely on the paved surface, without allowing the brakes to get too hot.

It's also important to ensure that a plane doesn't spend too long on the runway. At a busy airport such as London's Heathrow Airport (LHR), there is an aircraft landing every 50 seconds or so. One of the most common causes of go-arounds is the aircraft ahead taking too long to vacate the runway. As a result, pilots must decide which runway exit to take and plan the braking accordingly.

Related: The little-understood government rule that allows airlines to dominate certain airports

To help with this, the autobrake system provides automatic braking at a preselected rate as soon as the aircraft senses that it is on the ground.

Brake cooling schedule

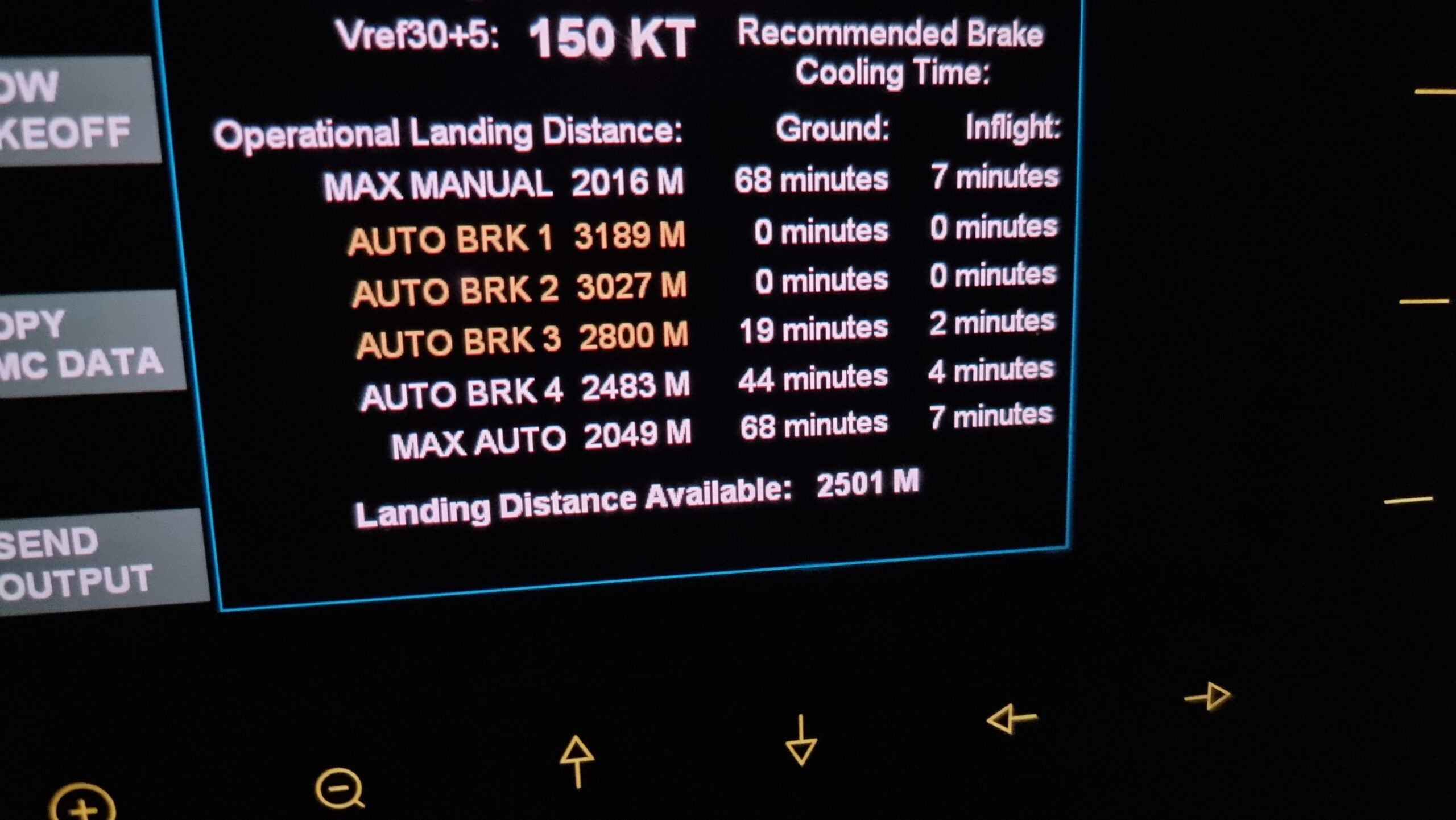

The landing data calculation takes the runway length, aircraft weight, landing speed and weather information into consideration to calculate how much runway a plane will use on a particular autobrake setting. On the 787, the onboard performance tool calculates this, and it conveniently provides the distance for each autobrake setting in an easy-to-see format.

After looking at the charts to choose a runway exit and determining how far down the runway this is, pilots can then select the autobrake setting that best fits with this number. However, there is one final check to be made: the brake cooling schedule.

The quick-reference handbook on the 787 is a thick spiral-bound book containing a wealth of technical data about the aircraft. Within its pages is a table that allows pilots to calculate how hot the brakes will get depending on the same data used in the onboard performance tool.

By working through the table with the selected settings, pilots can calculate how hot the brakes are expected to get when landing. At the cooler end of the spectrum, this details how long it will take for the brakes to cool before the aircraft can depart. At the hotter end, there is a chance that the fuse plugs may melt — a situation that should be avoided at all costs.

If pilots find that the current plan has the plane in the melt zone, or even in the caution zone, they must go back to the landing data calculation and find a way to reduce the amount of energy going into the brakes.

This might be accomplished by using a higher flap setting, using maximum reverse thrust instead of idle reverse or simply using a lower autobrake setting and taking up more of the runway length when stopping.

Too hot?

Most of the time, the weight of the aircraft, runway length and environmental conditions are no issue when it comes to selecting the autobrake. However, there are certain situations where experienced pilots know there may be a problem with the brake temperatures. One of these situations is when the outside air temperature is high.

In these scenarios, the brakes are unable to lose the heat as effectively as they would if the air temperature was cooler. As a result, there is a higher risk of the brakes overheating if they are not managed properly.

Having flown both the A320 family and the 787, I found that the brakes on the A320 tend to get warmer than those on the 787. Why this is, I cannot say for sure. In my personal experience, we would end up using the brakes more often on the taxi between the gate and the runway on the A320. This is due to the fact that the high idle engine power could result in the aircraft accelerating quite quickly and needing to be slowed down more often.

To help keep the brake temperature down, most A320-family aircraft now have brake fans. This enables the pilots to circulate air around the brake unit, increasing the rate of cooling, which helps prevent the brakes from getting too hot.

However, like with all things in aviation, incidents never happen for a single reason.

Should the crew get airborne with the brakes already warm from a long taxi out, they would have little chance to cool on a short flight. If they were to then land at a high weight on a hot day using a high braking force to get off the runway quickly, it's easy to see how the brake temperature could rocket.

Related: Can the weather get too hot to fly a plane safely? A pilot explains

Bottom line

There's a lot more thought that goes into landing than just throwing the aircraft on the runway and slamming on the brakes. Pilots must consider the effects their braking has not only on the comfort of their passengers but also on the brakes and the aircraft itself. A failure to consider all the factors that go into the landing, deceleration and taxi process can easily result in the brakes overheating.

However, if the brakes do get too hot, the tires are designed to automatically deflate once they reach a certain temperature to avoid exploding. In addition, the landing gear assembly design ensures that even if a fire breaks out, it will not spread to other parts of the aircraft.

In these situations, more often than not, it's safer for the pilots to keep everyone on board the aircraft instead of evacuating. Airports require that the fire services are able to reach any part of the airfield in a matter of minutes, so the fire will be extinguished before it causes any real harm to the aircraft and its occupants.

TPG featured card

Rewards

| 4X | Earn 4X Membership Rewards® points per dollar spent on purchases at restaurants worldwide, on up to $50,000 in purchases per calendar year, then 1X points for the rest of the year. |

| 4X | Earn 4X Membership Rewards® points per dollar spent at US supermarkets, on up to $25,000 in purchases per calendar year, then 1X points for the rest of the year. |

| 3X | Earn 3X Membership Rewards® points per dollar spent on flights booked directly with airlines or on AmexTravel.com. |

| 2X | Earn 2X Membership Rewards® points per dollar spent on prepaid hotels and other eligible purchases booked on AmexTravel.com. |

| 1X | Earn 1X Membership Rewards® point per dollar spent on all other eligible purchases. |

Intro offer

Annual Fee

Recommended Credit

Why We Chose It

There’s a lot to love about the Amex Gold. It’s a fan favorite thanks to its fantastic bonus-earning rates at restaurants worldwide and at U.S. supermarkets. If you’re hitting the skies soon, you’ll also earn bonus Membership Rewards points on travel. Paired with up to $120 in Uber Cash annually (for U.S. Uber rides or Uber Eats orders, card must be added to Uber app and you can redeem with any Amex card), up to $120 in annual dining statement credits to be used with eligible partners, an up to $84 Dunkin’ credit each year at U.S. Dunkin Donuts and an up to $100 Resy credit annually, there’s no reason that foodies shouldn’t add the Amex Gold to their wallet. These benefits alone are worth more than $400, which offsets the $325 annual fee on the Amex Gold card. Enrollment is required for select benefits. (Partner offer)Pros

- 4 points per dollar spent on dining at restaurants worldwide and U.S. supermarkets (on the first $50,000 in purchases per calendar year; then 1 point per dollar spent thereafter and $25,000 in purchases per calendar year; then 1 point per dollar spent thereafter, respectively)

- 3 points per dollar spent on flights booked directly with the airline or with amextravel.com

- Packed with credits foodies will enjoy

- Solid welcome bonus

Cons

- Not as useful for those living outside the U.S.

- Some may have trouble using Uber and other dining credits

- You may be eligible for as high as 100,000 Membership Rewards® Points after you spend $6,000 in eligible purchases on your new Card in your first 6 months of Card Membership. Welcome offers vary and you may not be eligible for an offer. Apply to know if you’re approved and find out your exact welcome offer amount – all with no credit score impact. If you’re approved and choose to accept the Card, your score may be impacted.

- Earn 4X Membership Rewards® points per dollar spent on purchases at restaurants worldwide, on up to $50,000 in purchases per calendar year, then 1X points for the rest of the year.

- Earn 4X Membership Rewards® points per dollar spent at US supermarkets, on up to $25,000 in purchases per calendar year, then 1X points for the rest of the year.

- Earn 3X Membership Rewards® points per dollar spent on flights booked directly with airlines or on AmexTravel.com.

- Earn 2X Membership Rewards® points per dollar spent on prepaid hotels and other eligible purchases booked on AmexTravel.com.

- Earn 1X Membership Rewards® point per dollar spent on all other eligible purchases.

- $120 Uber Cash on Gold: Add your Gold Card to your Uber account and get $10 in Uber Cash each month to use on orders and rides in the U.S. when you select an American Express Card for your transaction. That’s up to $120 Uber Cash annually. Plus, after using your Uber Cash, use your Card to earn 4X Membership Rewards® points for Uber Eats purchases made with restaurants or U.S. supermarkets. Point caps and terms apply.

- $84 Dunkin' Credit: With the $84 Dunkin' Credit, you can earn up to $7 in monthly statement credits after you enroll and pay with the American Express® Gold Card at U.S. Dunkin' locations. Enrollment is required to receive this benefit.

- $100 Resy Credit: Get up to $100 in statement credits each calendar year after you pay with the American Express® Gold Card to dine at U.S. Resy restaurants or make other eligible Resy purchases. That's up to $50 in statement credits semi-annually. Enrollment required.

- $120 Dining Credit: Satisfy your cravings, sweet or savory, with the $120 Dining Credit. Earn up to $10 in statement credits monthly when you pay with the American Express® Gold Card at Grubhub, The Cheesecake Factory, Goldbelly, Wine.com, and Five Guys. Enrollment required.

- Explore over 1,000 upscale hotels worldwide with The Hotel Collection and receive a $100 credit towards eligible charges* with every booking of two nights or more through AmexTravel.com. *Eligible charges vary by property.

- No Foreign Transaction Fees.

- Annual Fee is $325.

- Terms Apply.

Rewards Rate

| 4X | Earn 4X Membership Rewards® points per dollar spent on purchases at restaurants worldwide, on up to $50,000 in purchases per calendar year, then 1X points for the rest of the year. |

| 4X | Earn 4X Membership Rewards® points per dollar spent at US supermarkets, on up to $25,000 in purchases per calendar year, then 1X points for the rest of the year. |

| 3X | Earn 3X Membership Rewards® points per dollar spent on flights booked directly with airlines or on AmexTravel.com. |

| 2X | Earn 2X Membership Rewards® points per dollar spent on prepaid hotels and other eligible purchases booked on AmexTravel.com. |

| 1X | Earn 1X Membership Rewards® point per dollar spent on all other eligible purchases. |

Intro Offer

You may be eligible for as high as 100,000 Membership Rewards® Points after spending $6,000 in eligible purchases on your new Card in your first 6 months of Membership. Welcome offers vary and you may not be eligible for an offer.As High As 100,000 points. Find Out Your Offer.Annual Fee

$325Recommended Credit

Credit ranges are a variation of FICO® Score 8, one of many types of credit scores lenders may use when considering your credit card application.Excellent to Good

Why We Chose It

There’s a lot to love about the Amex Gold. It’s a fan favorite thanks to its fantastic bonus-earning rates at restaurants worldwide and at U.S. supermarkets. If you’re hitting the skies soon, you’ll also earn bonus Membership Rewards points on travel. Paired with up to $120 in Uber Cash annually (for U.S. Uber rides or Uber Eats orders, card must be added to Uber app and you can redeem with any Amex card), up to $120 in annual dining statement credits to be used with eligible partners, an up to $84 Dunkin’ credit each year at U.S. Dunkin Donuts and an up to $100 Resy credit annually, there’s no reason that foodies shouldn’t add the Amex Gold to their wallet. These benefits alone are worth more than $400, which offsets the $325 annual fee on the Amex Gold card. Enrollment is required for select benefits. (Partner offer)Pros

- 4 points per dollar spent on dining at restaurants worldwide and U.S. supermarkets (on the first $50,000 in purchases per calendar year; then 1 point per dollar spent thereafter and $25,000 in purchases per calendar year; then 1 point per dollar spent thereafter, respectively)

- 3 points per dollar spent on flights booked directly with the airline or with amextravel.com

- Packed with credits foodies will enjoy

- Solid welcome bonus

Cons

- Not as useful for those living outside the U.S.

- Some may have trouble using Uber and other dining credits

- You may be eligible for as high as 100,000 Membership Rewards® Points after you spend $6,000 in eligible purchases on your new Card in your first 6 months of Card Membership. Welcome offers vary and you may not be eligible for an offer. Apply to know if you’re approved and find out your exact welcome offer amount – all with no credit score impact. If you’re approved and choose to accept the Card, your score may be impacted.

- Earn 4X Membership Rewards® points per dollar spent on purchases at restaurants worldwide, on up to $50,000 in purchases per calendar year, then 1X points for the rest of the year.

- Earn 4X Membership Rewards® points per dollar spent at US supermarkets, on up to $25,000 in purchases per calendar year, then 1X points for the rest of the year.

- Earn 3X Membership Rewards® points per dollar spent on flights booked directly with airlines or on AmexTravel.com.

- Earn 2X Membership Rewards® points per dollar spent on prepaid hotels and other eligible purchases booked on AmexTravel.com.

- Earn 1X Membership Rewards® point per dollar spent on all other eligible purchases.

- $120 Uber Cash on Gold: Add your Gold Card to your Uber account and get $10 in Uber Cash each month to use on orders and rides in the U.S. when you select an American Express Card for your transaction. That’s up to $120 Uber Cash annually. Plus, after using your Uber Cash, use your Card to earn 4X Membership Rewards® points for Uber Eats purchases made with restaurants or U.S. supermarkets. Point caps and terms apply.

- $84 Dunkin' Credit: With the $84 Dunkin' Credit, you can earn up to $7 in monthly statement credits after you enroll and pay with the American Express® Gold Card at U.S. Dunkin' locations. Enrollment is required to receive this benefit.

- $100 Resy Credit: Get up to $100 in statement credits each calendar year after you pay with the American Express® Gold Card to dine at U.S. Resy restaurants or make other eligible Resy purchases. That's up to $50 in statement credits semi-annually. Enrollment required.

- $120 Dining Credit: Satisfy your cravings, sweet or savory, with the $120 Dining Credit. Earn up to $10 in statement credits monthly when you pay with the American Express® Gold Card at Grubhub, The Cheesecake Factory, Goldbelly, Wine.com, and Five Guys. Enrollment required.

- Explore over 1,000 upscale hotels worldwide with The Hotel Collection and receive a $100 credit towards eligible charges* with every booking of two nights or more through AmexTravel.com. *Eligible charges vary by property.

- No Foreign Transaction Fees.

- Annual Fee is $325.

- Terms Apply.